If you’ve ever had a leaky faucet, you’ve seen a faucet valve in action—or inaction, as the case may be. In fact, the valve is the part most likely to break in a faucet. Basically, a faucet valve controls the flow of water and, in single handle faucets, the temperature of that water. Between its many components and how much work it does in controlling the flow of water, your faucet valve is a very important part.

Here we’ll discuss the most common valves found in sink and bathtub faucets, what types of faucets they’re most likely to be found in, and how they work. We’ll also talk about how to identify a particular type of valve and how easy these valves are to repair and replace.

Types of faucet valves

While all faucet valves control the flow of water, there are several different ways they do this. Faucet valves began as simple plugs that had to be pried open and hammered closed. Today, there are a variety of valve mechanisms available on the market.

Whether you’re looking for sink faucets, tub faucets, or shower faucets, your setup is likely to use one of these. We’ll talk about mixing valves (that combine hot and cold water in tubs and showers) and diverter valves (that transfer water flow from the tub spout to the showerhead) in the next section.

Ceramic disc faucet valves

Ceramic disc valves are the newest type of faucet valve and tend to come in higher-end faucets. While older-style faucet valves use a series of rubber washers to control the flow of water, these use two small ceramic disks. These disks are ground to be very smooth, with a series of channels cut into them. The disks are pressed tightly together with the channels unconnected when the faucet is turned off. When the faucet is turned on, the disks are rotated until the right channels align.

Faucets using these valves can be either single or double handled, with hot and cold water mixing either in the spout or in the valve itself. Sink faucets with these valves tend to have wider bodies than faucets that use other kinds of valves, but ceramic disk valve bathtub faucets come in a variety of styles. The only way to be sure that a particular faucet has a ceramic cartridge is to check with the manufacturer or take the faucet apart.

Ceramic discs have significant advantages over older styles of faucet valves. The disks themselves are very hard, making them unlikely to chip and pit. They’re ceramic, not metal, meaning they don’t corrode. These valves can last for years without damage, and it’s usually the o-rings that hold the cartridge in place, rather than the cartridge itself, that tend to wear out.

Unfortunately, one of the main advantages of the ceramic disk valve is also one of its weaknesses. When not in use, faucets with these valves rarely leak, since the ceramic disks are held together so tightly. But this also means that in order to move, the disks have to be lubricated. This lubricant (usually a silicone-based plumbing grease) will be worn away by use.

Thankfully, you don’t necessarily have to replace the entire ceramic disk valve when it needs lubrication. The disks can generally be relubricated and the o-rings replaced, meaning these valves can last for years with careful maintenance. If you do have to replace the whole cartridge, expect to pay around ten to thirty dollars depending on model and seller.

| Ceramic Disk Valve Features | |

| Found in: | Kitchens and bathrooms. Modern homes. |

| Handle type: | Single or double handle |

| Durability and maintenance: | Almost leak proof. Will last for several years and <em>can</em> be repaired. Cartridge can be replaced fairly easily. |

| Cost: | $10-$30 for cartridge replacement, though bathtub/shower cartridges can be a bit more. O-rings and silicone grease are easy to find. |

Ball faucet valves

Ball faucet valves were originally developed in the 1950s for use in Delta faucets, and Delta still uses ball valves for most of their faucets. These valves feature a ball with a series of holes that allows hot and cold water to mix before being expelled from the faucet. This ball is held by a cup-shaped piece called a cam and kept in place with a series of washers and springs.

Because of this design, ball valves are relatively fragile. They have many parts that can fail, and they’re harder to repair than disk and cartridge valves. Ball valves are especially susceptible to damage from the minerals in hard water as the surface of the ball can become worn.

Faucets that use ball valves are almost always single handle. These valves are most popular in kitchen faucets, though bathroom faucets with ball valves are available.In sink faucets, the faucet body is rounded on top, with a handle that twists upward, as well as side-to-side. In bathtub faucets, they often have ball shaped handles.

While ball valves (as well as disk and cartridge valves) are sometimes called washerless, it’s important to know that this isn’t entirely true. In fact, ball valve faucets generally contain a number of washers and o-rings that help hold the ball in place. What makes a washerless valve is that these parts don’t have to take the force of the handle, meaning they wear out much more slowly than in older valves.

| Ball Valve Features | |

| Found in: | Kitchens and bathrooms, but especially in kitchen sink faucets. |

| Handle type: | Single handle |

| Durability and maintenance: | Many complicated parts that can fail. Especially bad with hard water. Not especially easy to repair or replace. |

| Cost: | $10-$40 for a full repair kit, with bathtub/shower faucet valves being more expensive. However, many parts for ball valves can be purchased individually at a lower price point. |

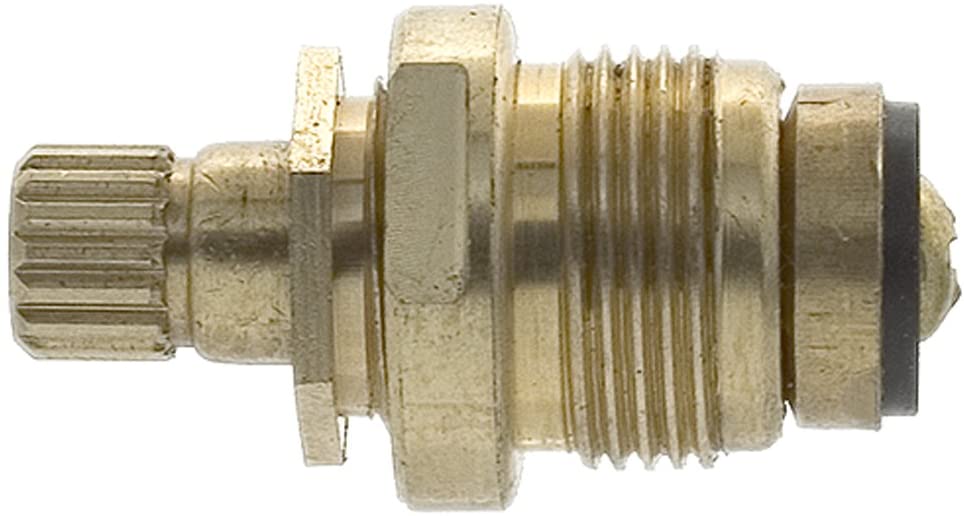

Cartridge faucet valves

Cartridge faucet valves were first developed by Moen in the 1930s. These valves replaced the older washer-based style with a new cartridge system. Like ball valves, there is a central piece which is moveable, allowing hot and cold water to mix before flowing out of the tap. Instead of a ball, cartridge valves have a cylinder which is raised and lowered to allow water to flow.

Unlike ball valves, though, cartridge valve faucets are generally available in single or double handled configurations. Single handle cartridge sink faucets may be a little slimmer in construction than ceramic disc or ball valve faucets, but designs do vary. The double handle version is basically indistinguishable from older compression valve faucets, especially with bathtub faucets, though the handles tend to be easier to turn.

The main advantage of a cartridge valve is that instead of replacing individual parts, you can simply replace the entire cartridge at once. While these valves can be complicated in construction, replacement is much easier than repair. This may mean, however, that repair will generally be more expensive.

Instead of buying a specific washer or screw, you will almost always need to replace the entire valve assembly. These cartridges can be anything from $10-$40 dollars, on average, which is definitely more expensive than a washer or two. However, these cartridges can last for years, and if you’re reasonably comfortable with DIYing, you should be able to replace these valves on your own. You can even sometimes upgrade your cartridge valve faucet to a ceramic disc faucet.

| Cartridge Valve Features | |

| Found in: | Kitchens and bathrooms |

| Handle type: | Single or double handle |

| Durability and maintenance: | Few parts to break, though not as durable as ceramic disks. Repair can be complicated, but replacing is easy. |

| Cost: | $10-$40 for a replacement sink cartridge and $20-$60 for shower cartridges, though heavier duty models may be more expensive. Individual parts of the cartridge are harder to find, though a few kits are available. |

Compression washer valves

Compression valves are the oldest style of sink faucet valve still available. They’re simple in construction, consisting of a stem with a washer attached to the bottom. When the handle is turned, the stem twists, raising the washer and allowing water to flow.

This design means that these valves only work with double handle faucets, since each stream of water (hot and cold) has to be controlled by its own valve. While triple handle bathtub/shower faucets (ones with hot, cold, and diverter spigots) don’t have to have compression valves, almost all compression valves are used in this style. This design also means that you generally have to turn the faucet farther to turn the water on. These faucets often have to be tightened considerably to keep the tap from leaking.

The mechanical process of opening and closing the faucet puts a lot of strain on the washers, so they tend to wear down fairly quickly. These faucets are the most likely to drip out of all modern designs. The simplicity of this design, though, also means that repair is relatively simple.

| Compression Washer Valve Features | |

| Found in: | Utility sinks, laundry room faucets, outdoor spigots. Kitchens and bathrooms in older homes. |

| Handle type: | Double handle only for sink. For bathtub/shower, typically triple handle construction. |

| Durability and maintenance: | Rubber washer can fall apart and will have to be replaced fairly regularly (every couple of years). Repair is relatively simple. |

| Cost: | Around $10-$30 for a stem, though replacement parts are less likely to come in kits. You may have to purchase individual components separately. |

Types of bathroom faucet valves

While showers and bathtubs still use ceramic disc, ball, cartridge, and compression valves behind their handles, showers and bathtubs can be a little more complicated. Alongside these valves, some kind of mixing valve will be required. In addition, bathtub/shower combos will need a diverter valve.

One term you’re likely to see when looking into shower and tub valves is rough-in. A rough-in valve has inlet ports for unmixed hot and cold supply lines. Rough-in valves are always mixing valves, but may also perform other functions. If you’re renovating your bathroom and would like to make your tub or shower is more DIY friendly, consider a rough-in valve with integral (or screwdriver) stops. These function like the water shutoff valves under the sink and let you repair your fixtures without having to shut water off to the entire house.

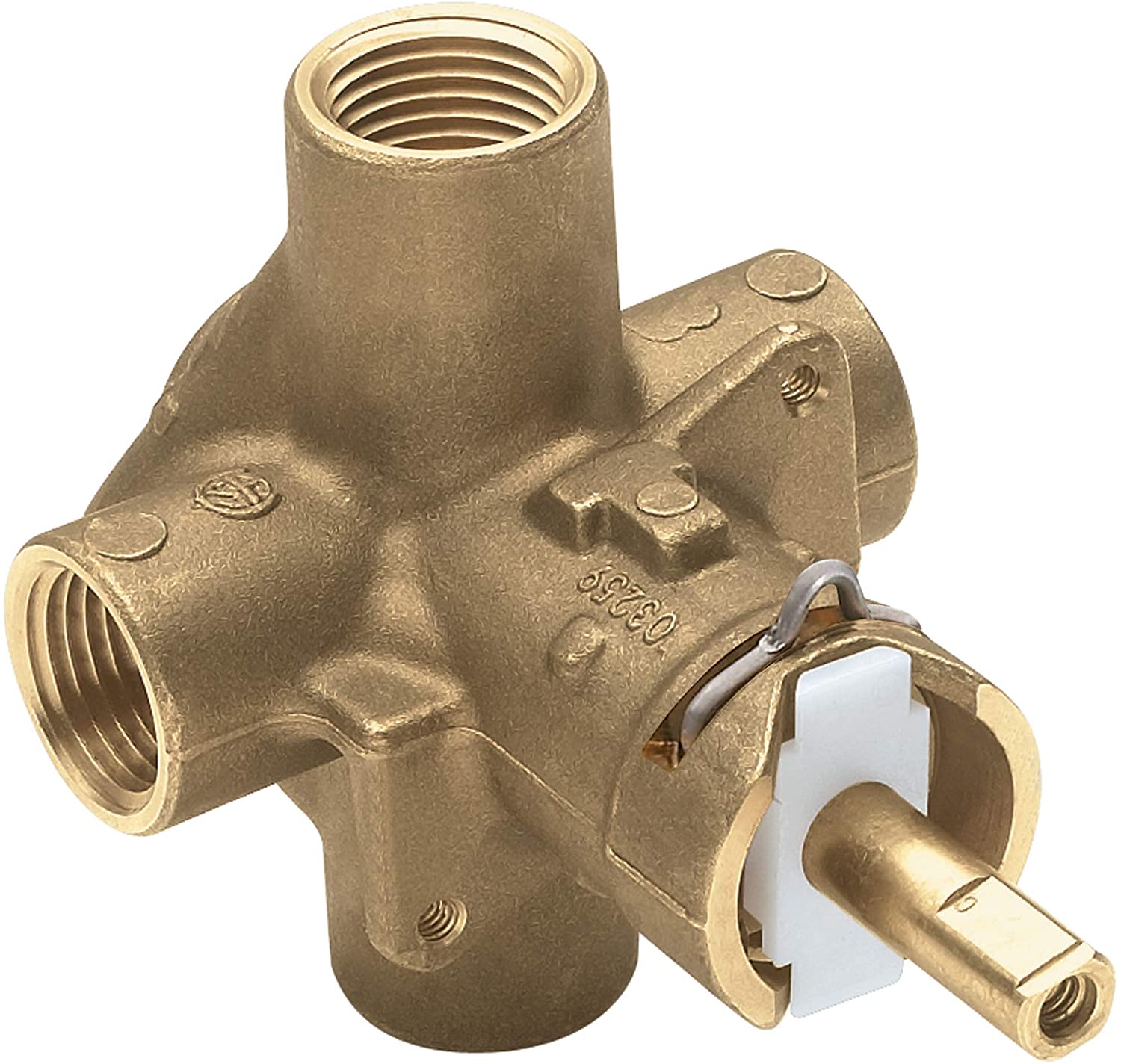

Pressure balancing valves (anti-scald valves)

Pressure balancing valves are a type of mixing valve that keeps the water pressure in a shower constant, which also keeps the temperature more stable. These valves are also called anti-scald valves.

Pressure balancing valves don’t actually sense temperature. What they do is in the name: they balance pressure. There’s a piston between the hot and cold supply that moves according to the relative pressure of each line. When water is used elsewhere in the home, causing a drop in pressure in one of the lines, the piston prevents the water temperature from changing dramatically, keeping it within about 5 degrees fahrenheit from the target temperature (±3°C)

On its own, a pressure balancing valve can’t prevent scalding, however. Depending on the temperature your hot water heater is set on, the water can still get way too hot if you turn the handle too far. To prevent this, most pressure balancing valves have a part called a limiter. This is a screw controlled part which is normally hidden under the shower handle trim and can be adjusted to keep the maximum temperature of the water flow at or under 120°F (50°C).

While bathtubs without showers don’t necessarily historically have mixing valves, most modern regulations require some form of anti-scald protection. While some pressure-balancing valves are compatible with lone bathtubs, these valves can also be called tempering valves.

| Pressure Balancing Valve Features | |

| Found in: | Most newer homes |

| Handle type: | Single handle, or double with diverter handle |

| Durability and maintenance: | Can last for many years, though the piston can stick. Maintenance can be complicated, as these valves are compatible with cartridges, ball valves, and compression assemblies. |

| Cost: | $50-$125 |

Thermostatic valves

Thermostatic valves are a newer, more high tech kind of mixing valve that does directly regulate temperature. They keep the water temperature very steady and offer the highest level of control of both water temperature and flow rate. These valves are mainly designed for showers, but some high-end sink faucets have thermostatic capabilities.

Thermostatic valves have pistons like pressure balancing valves, but instead of being controlled by water pressure, they’re controlled directly by temperature. These valves have a small plug made out of a thermostatic element (usually wax) that expands and contracts with changes in temperature. This plug pushes the piston, which begins to close off the hot water flow as the temperature increases.

When the temperature decreases, the plug gets smaller. A spring on the other end of the piston pushes it back against the plug, increasing hot water flow again. This keeps the temperature within less than a degree fahrenheit of the target temperature (±1°C) no matter the water pressure. Like pressure balancing valves, these valves often come with limiters for additional scald protection.

Digital thermostatic valves are also available. Instead of a two (or three, with diverter) handle system, these can have one or none at all. The thermostatic valve is paired with a digital controller that lets you choose the exact temperature (and sometimes flow rate) that you want. You can even set programs for your daily routines. The only downside is the cost, as these systems are about $300 on the low end.

| Thermostatic Valve Features | |

| Found in: | Higher end showers |

| Handle type: | Usually double (one for temperature, one for flow) or triple (with a diverter handle) |

| Durability and maintenance: | There are more parts that can fail, but these valves tend to come with higher quality components. For maintenance, simply replace the cartridge. |

| Cost: | $70-$150 |

Mixing valves

If you’ve ever found yourself frozen (or scalded) in the shower because someone flushed the toilet or ran the dishwasher, you know what a basic mixing valve is like. At its most simple, a mixing valve is basically a y-connector, like what exists in some two handle sink faucets. Hot and cold water come in, and warm water goes out. Common in older homes, these valves are no longer recommended because of the dangers of scalding.

In fact, in most places these valves can no longer be installed in new homes. In a number of areas, plumbing codes require them to be removed if the bathroom is renovated. Check with local and state regulations to be sure. Generally, though, if you can switch to a pressure balancing or thermostatic valve, you should. If you can’t, make sure that your hot water heater is set to 120°F (50°C).

| Mixing Valve Features | |

| Found in: | Older homes |

| Handle type: | Double and triple handle |

| Durability and maintenance: | These valves have few moving parts and routinely last for decades. If your mixing valve is in need of repair, consider replacing it instead if possible. |

| Cost: | As this style is no longer up to code in most jurisdictions, you’ll have a very hard time buying these new. Repair kits tend to be $30-$60. |

Diverter valves

Bathtub/shower combos also have a part called a diverter valve. This valve determines whether water comes out of the tub spout or the showerhead. There are a few different ways to engage the diverter depending on the shower, but the valve itself generally functions the same way. Water comes into the diverter and then flows out one outlet at a time.

The smallest shower diverters are three way, with one inlet (transferring water that’s already gone through a mixer valve) and two outlets. The largest most commonly available diverters are five way, with two inlets (for hot and cold, making these also rough-in valves) and three outlets. If a diverter has more outlets than necessary, they can be plugged.

Water can be transferred between outlets in a number of ways. Most older systems have a diverter handle that is turned to turn the shower on. Some tub/shower combos have the diverter mechanism on the tub spout in either a pull up (also called a tee diverter for the shape of the part) or a pull down (on the mouth of the spout) mechanism. Some diverters are push button activated. The style you choose is likely to determine what kind of diverter you need.

Some mixing valves have integrated diverters. In fact, many single-handle pressure balanced valves are an all-in-one solution for all your valve needs. These can be more expensive overall, but they require fewer parts and are much easier to repair and replace.

One type of diverter valve that’s a bit more complicated is called a transfer valve. These valves work very similarly to diverter valves except that they can split the flow of water between multiple showerheads or faucets. These are generally only found in large, walk-in showers and are often paired with digital thermostatic valves for a high-end system.

| Diverter Valve Features | |

| Found in: | Bathtub/shower combos |

| Handle type: | Any, though triple handle setups have a handle just for the diverter |

| Durability and maintenance: | Diverter valves tend to last for a couple of decades. Depending on design |

| Cost: | $15+ for regular diverters with integrated mixing valves retailing for over $100. Transfer valves start at around $125. |

Making sense of valve connection terminology

If you’ve ever looked up shower/tub valves online or looked at a store’s selection, you might have found yourself overwhelmed by the number of types of connections that seem to be available. While only you (or whoever you may hire) will know exactly which connections are necessary for your setup, we will briefly break down the terms and acronyms so you have somewhere to start.

- Female fittings have threads on the inside, while male fittings have threads on the outside. A plain end (PE) pipe has no threads.

- NPT stands for National Pipe Taper Thread. It’s a standardized tapered, threaded pipe. It has two subtypes, FPT (Female Pipe Thread) and MPT (Male Pipe Thread).

- IPS stands for Iron Pipe Sizing. It’s an older sizing method that is about the same as (and generally fits with) NPT. Its variants are FIP (Female Iron Pipe) and MIP (Male Iron Pipe). Despite the name, they do not have to be made of iron.

- GHT stands for Garden Hose Thread. As the name suggests, it’s more common for outdoor and utility plumbing. Its variants are FHT (Female Hose Thread) and MHT (Male Hose Thread).

- A compression fit (or comp) is tightened by a compression nut. The nut is slid onto the pipe alongside a ring and then tightened down, creating a watertight seal.

- A sweat fit is made by heating a copper pipe with a propane torch until it’s hot enough to melt solder (a soft metal alloy with a low melting point). The solder is pulled into the gap until the pipe cools, forming a watertight seal.

- A crimp fit is similar to a compression fit, but instead of a compression nut, the ring is tightened down with a crimping tool.

- A barb fit works with flexible piping, where one hose is pressed into another and a series of ridges or bumps are used to form a mechanical connection.

- A flange fitmakes use of a flange, a flat, collar-shaped piece that stabilizes a connection.

What to look for in a faucet valve

The first and most important thing to look for in a faucet valve is that it fits in your faucet. Once you have a faucet, you don’t have many choices of valve. The faucet itself determines which type of valve will be compatible, so when choosing a new faucet, make sure to see what kind of valve it has if this is a component that matters to you.

Besides type of valve, then, another consideration is whether repair kits and replacement parts are widely available. The faucet valve is often the failure point of the faucet, so being able to repair or replace your valve at an affordable price is important. Consider a widely available name brand for the best repair and replacement options, and don’t forget about the warranty. Some faucets come with guaranteed free replacement parts.

The difference between hot and cold faucet valves

One important distinction in two handled cartridge valves (as well as two handled ceramic disc valves) is between hot and cold. Often marked with a red line (for hot) or a blue line (for cold), these cartridges are not interchangeable. Cold cartridge valves are designed to be opened with a clockwise motion; hot valves are the other way round.

Unless you want a surprise, make sure to install these cartridges in the right order. Don’t try to fit single handle cartridges into double handle faucets unless they’re listed as the correct replacement part.

Faucet valve materials

Finally, material is especially important. Not only do parts of the faucet valve come into contact with the water that flows through the faucet, they’re also often under significant stress when the faucet is turned on and off, meaning their materials could begin to break down and leach into your water. Faucet valve stems and bodies are traditionally made out of brass, but in recent decades, stainless steel, aluminum, zinc alloy, and various plastics have become commonplace.

This is not a situation where all plastic parts are inherently bad, though it’s advised to avoid PVC. Plastic housing for cartridges isn’t generally an issue, but for parts that undergo a great amount of force—like stems and the ball in a ball valve—brass, stainless steel, or aluminum are preferred.

Falling on the softer side and often found in cheaper faucet valves, zinc alloys are not preferred and should be avoided if possible. For the best long-term results, stick with metal parts, especially on the hot water line. Though plastic does have one great advantage over brass—there is absolutely no lead in it.

Brass parts in faucets are regulated to have less than 0.25% lead by weight to call themselves lead-free. Having brass parts in faucets is generally considered safe, but if you are concerned, try to avoid brass along the entirety of your water line.

For bathtub/shower valves there’s an additional concern: galvanic corrosion. Galvanic corrosion happens when two different metals are attached together while being in contact with an electrolyte (which water can act as). This basically makes your pipes into a weak battery, where ions are transferred from one metal to another.

This means that if you put the wrong metals up against each other, one of them will corrode. The best option is to match the metal of your valves to the metal of your pipes and other fittings. But this isn’t always possible. Generally, in plumbing, the problem comes with attaching copper to galvanized steel (that is, steel that has been coated with zinc). A short piece of brass piping between any copper and galvanized steel parts can prevent most corrosion.

DIY faucet valve repair

Sink faucets can be daunting for the amateur DIYer, but they don’t have to be. While compression and ball valves can be difficult to repair, ceramic disc and cartridge valves are usually easy to replace. Hiring a plumber to fix a leaky faucet can cost $200-$300, but having a faucet replaced can cost even more.

If you’d like to try your hand at repairing your faucet’s valve, there are a few things you’ll need. You’re going to want a set of tongue and groove pliers (also called channellocks) or a faucet handle puller, especially for older faucets. For tubs and showers, you may want a tub socket wrench. You’ll also want an appropriately sized allen wrench for the set screw that holds the faucet together. Flat and phillips head screwdrivers and a crescent wrench are also good to have.

When doing any repair involving multiple parts, it’s important to know how to put everything back together. Consider lining up the parts in the order you remove them or taking pictures after each step so no part is lost. Close the drain, or cover it with a rag to keep small parts from falling in, and always make sure to turn off the water (whether under the sink, inside the shower or tub wall, or, if all else fails, at the home shutoff valves) before you start!

For more complicated valves, like diverter and mixing valves, you’re more likely to need help. Any repair or replacement job that involves cutting into the wall is going to require a professional unless you already know what you’re doing.

Check out the videos below to learn more about repairing various faucet valves: